DATRON technology provides a full range of production advantages:

- High-quality results and short processing times due to fast digital servo controls, high-frequency spindles and optimal accessories

- Efficiency in acquisition through modular adaptation to manufacturing tasks

- High machine availability thanks to proven and tested quality and fast service

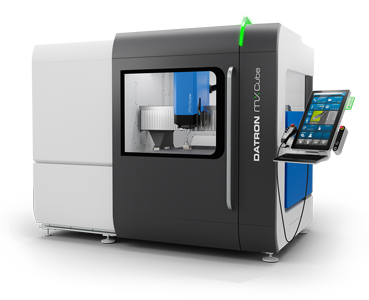

We present the DATRON MXCube, the premium class of our high-speed portal machines!

The rigid structure, maximum dynamics and a powerful high-frequency spindle are ideal for modern HSC strategies and can combine high machining volume with outstanding surface finish. The completely redesigned machine with optimised chip concept offers a wide range of functions for operation in an industrial environment.

Your production challenges drive our solutions.

The DATRON M8Cube is a high performance HSC milling machine that is both versatile and extraordinarily efficient at a reasonable expense.

Your production efficiency is the key aspect among many M8Cube advantages you will benefit from:

- High dynamics through optimized controls with a focus on acceleration and stiffness designed mechanical design.

- Very high tension power for small tools by using high-speed precision spindles with up to 60,000 1/min and services available from 0.6 kW to 4.0 kW.

- Rigid, low-vibration design of the machine for excellent surface quality when machining.

- High accuracy by high value linear guidance, Ball screws, HSK-E 25 tool holder (optional), and precision-crafted structure elements.

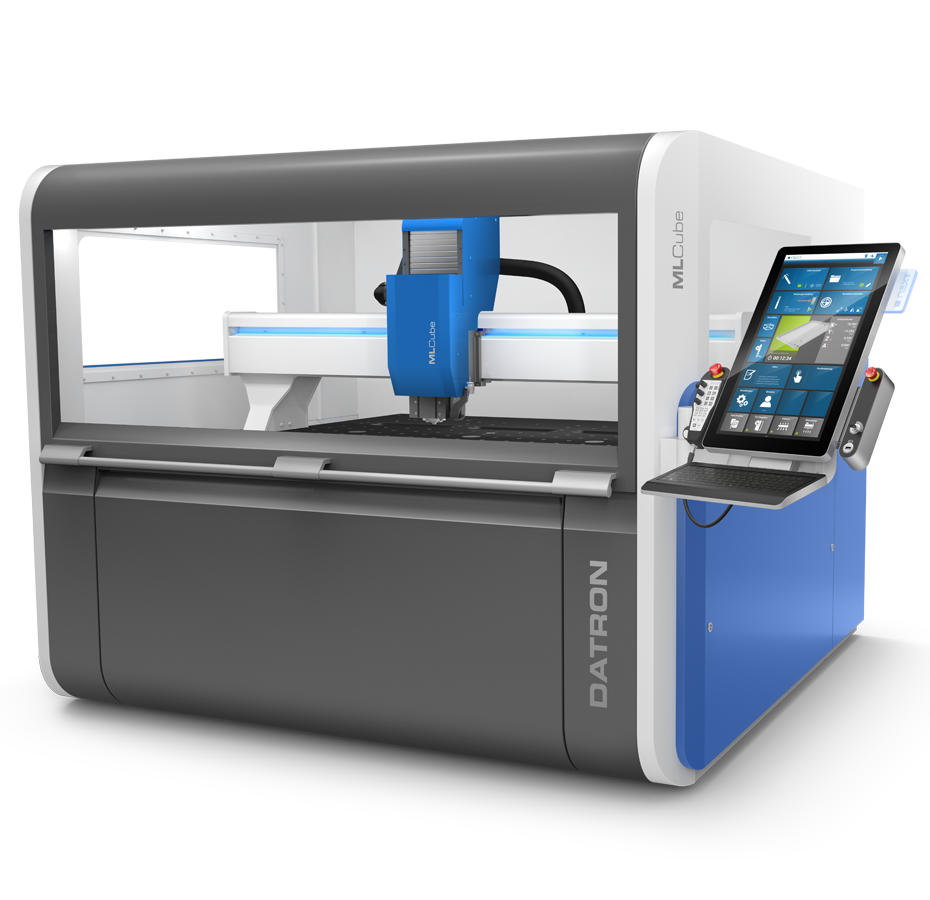

Large-format, fast and dynamic

The DATRON MLCube is the best choice for cost-effective sheet machining, for example, for the production of front panels, housings, profiles and other aluminium workpieces milled in nested form.

Other non-ferrous metals or composite materials can also be processed most efficiently with the MLCube. Its short setup times and its ability to use different clamping techniques simultaneously, its very low power consumption and its excellent price-performance ratio – even for low production volumes – provide long-term and extremely high profitability

Simpler. Quicker. Smarter.

DATRON neo was specifically designed and purpose-built to give you an easy access to high-speed milling. This Plug-and-Play system features the new DATRON next software which gives you full control of 3-axis milling without requiring years of experience as a machinist. Ergonomic, frontal access to the work area allows for quick and safe setup of workpieces. With a Smartphone-like (touch screen) interface the command of fast and precise machining is literally at your fingertips. All of this and DATRON neo actually fits through a standard door!

Volumetric Dispensing Machine with small workspace

With proven constant-volume dispensing systems DATRON sets the standard in the field of industrial dispensing for small and medium-sized components. At the heart of the dispensing system are different, exchangeable dispensing heads which can apply a large range of dispensing and materials and adhesives. With special DATRON accessories, e.g. module clamping systems or CAD/CAM software, set-up times are drastically reduced and productivity significantly increased. Further features such as the automatic nozzle compensation or the XYZ sensor lead to very high process reliability and repeatability also when dispensing critical components.

We are at your disposal:

Markus Haubenreich

Sales and Technology Consulting CNC & Dispensing Systems

Phone: +49 160 3626581

Mail: markus.haubenreich@datron.de